Desiccant Dehumidification

Desiccant Dehumidification Solutions

HVAC units engineered to deliver precision control in critical environments.

HVAC Solutions with Desiccant Dehumidification

Desiccant dehumidification air handling systems are used in applications that require cool and extra dry supply air, down to 15 grains, to prevent condensation or mold/fungus from forming.

Applications

- Specialized manufacturing environments

- Laboratories

- Operating rooms

- Ice arenas

- Storage

- Art galleries

XeteX desiccant dehumidification equipment can be customized and sized for any application. Unique to this type of system is the use of a specialized Desiccant wheel. Depending on the amount of dehumidification required, regeneration of the wheel may require temperatures reaching 300F.

Custom Desiccant Dehumidification

Design Features:

- 2”, 3" or 4” injected foam casings

- True thermal break panels and doors

- Thermal insulation barrier added to furnace compartment (for High-Temp Regen systems)

XETEX FEATURED

Desiccant Dehumidification Solutions

Custom RTU with Desiccant Dehumidification and Active Regen for Healthcare

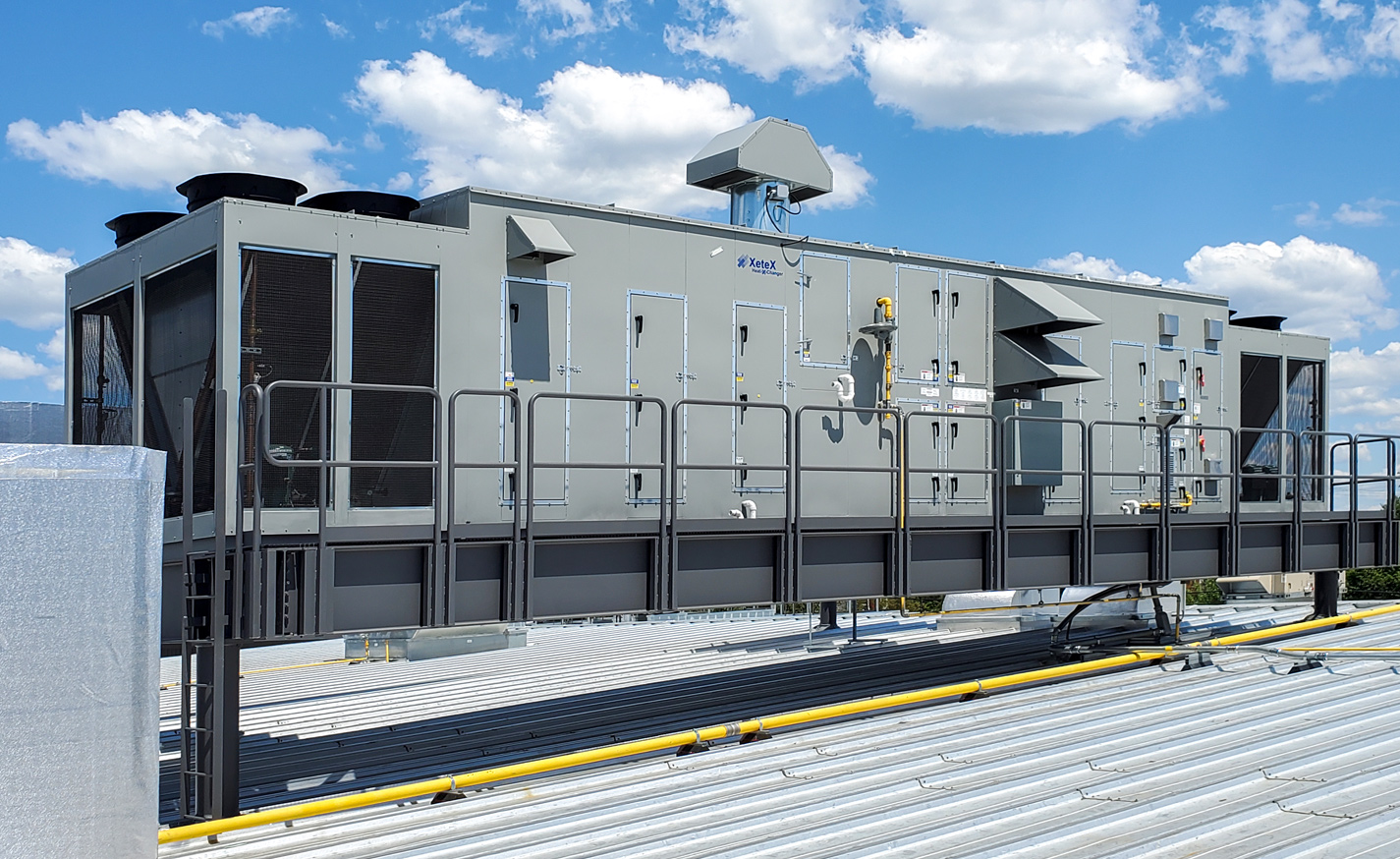

Specifically engineered for a medical application, this XeteX project features of one of eight custom roof top units equipped with cutting-edge desiccant dehumidification.

Custom RTU with Desiccant Dehumidification for a Surgical Center

This XeteX custom rooftop unit (RTU) with desiccant dehumidification was designed specifically for the critical needs of a surgical center.

Custom RTU with Desiccant Dehumidification for a Surgical Suite

Designed for a surgical suite to meet precise low dew point requirements, this custom RTU features a desiccant dehumidification energy wheel, packaged DX refrigeration, and a steam humidifier manifold.

Custom RTU with Desiccant Dehumidification for an Ice Arena

Designed for an ice arena, this XeteX custom AHU features a high-capacity active regen energy recovery wheel with heat reactivating H4M molecular sieve desiccant. It removes up to 296 lbs. of moisture per hour.

Find an XeteX Rep near You

XeteX collaborates with Sales Representatives and Engineers to understand your application and heating, cooling, ventilation, and dehumidification needs. Then we design and manufacture high performing, long lasting, energy efficient air handling and ventilation solutions geared to helping your building breathe better and perform to its greatest potential.