Energy Recovery Ventilation

Energy Recovery Ventilation

XeteX uses state-of-the-art energy recovery technologies to deliver the highest effectiveness for commercial and industrial applications.

Energy recovery technologies are used in XeteX HVAC equipment to reduce energy consumption, save resources and money, and improve indoor air quality.

Energy recovery technologies

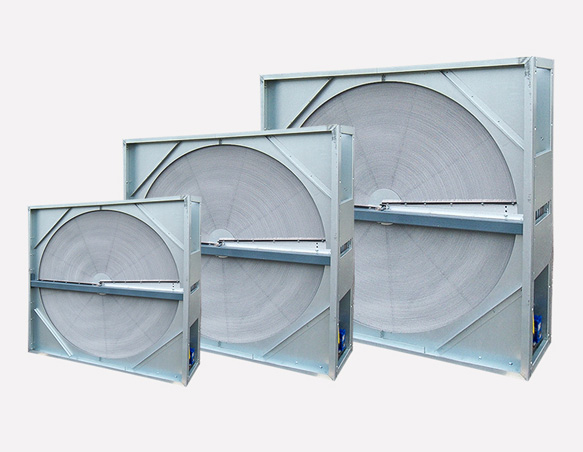

- Energy Recovery Wheels (Sensible Only and Latent)

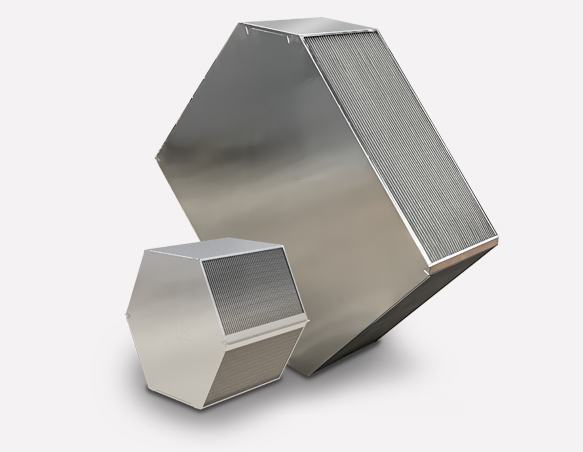

- Cross Flow Flat Plate Heat Exchangers (Sensible Only or Enthalpy)

- Counter Flow Plate Heat Exchangers (Sensible Only and Latent)

- Heat Pipes (Sensible Only)

- Run-Around Coils (Sensible Only)

How energy recovery technologies work

Energy recovery technologies use the temperature and humidity from return air to condition the incoming outdoor air. This process enhances air quality by increasing fresh air intake and improving air exchange, which help dilute and remove harmful elements from recirculated air in HVAC systems.

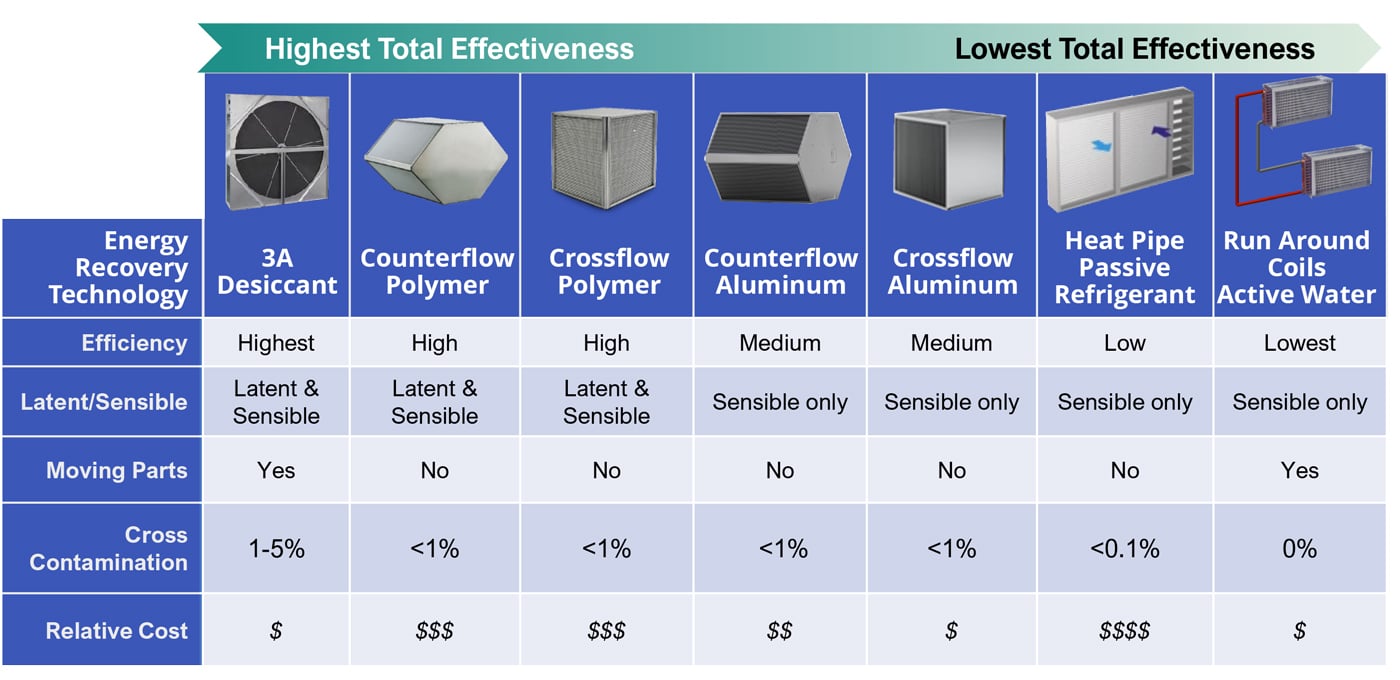

Energy Recovery Technology Comparison

XeteX draws from a variety of energy recovery technologies including Energy Recovery Wheels; Cross Flow Plate Heat Exchangers; Counter Flow Heat Exchangers; Heat Pipes; and Run-Around Coils.

The chart shows these technologies ranging in energy recovery effectiveness, maintenance with moving parts, cost and cross contamination.

XeteX optimizes system designs to deliver the highest Recovery Efficiency Ratio (RER)

The RER is a metric used to compare energy recovery device efficiency. It reflects the impact of pressure loss through the device as parasitic fan power. Higher RER values produce higher energy savings.

AVENTUS by XeteX

Semi-Custom Energy Recovery Ventilator (ERV)

The AVENTUS ERV provides XeteX-quality in a semi-custom solution with highly efficient enthalpic or sensible-only energy recovery technology.

Advantages of a Semi-Custom AVENTUS ERV

- Flexible duct configurations

- Multiple exterior and interior construction materials

-

Includes fans and filters with final filter options and more

State-of-the-Art Energy Recovery Technologies

FEATURED XETEX

Custom Energy Recovery Units

Custom ERU for an Airport

As part of the Buy America Build America program, this XeteX Basis of Design project highlights one of 27 custom ERUs for airport terminal restrooms—equipped with energy recovery enthalpic flat plate heat exchangers, an all-aluminum construction and heresite-coated coils.

Custom ERU for a Pharmaceutical Lab

Equipped with an epoxy-coated flat plate heat exchanger, this XeteX custom ERU efficiently recovers energy, maximizes energy savings, and is designed for long life to withstand the environment.

Custom Indoor ERV with an Active Regen Desiccant Wheel & Enthalpy Wheel

Custom ERU for a Pharmaceutical Manufacturer

This XeteX custom energy recovery unit serves a pharmaceutical lab space where precise control of the temperature and humidity are critical featuring an aluminum flat-plate heat exchanger.

Find an XeteX Rep near You

XeteX collaborates with Sales Representatives and Engineers to understand your application and heating, cooling, ventilation, and dehumidification needs. Then we design and manufacture high performing, long lasting, energy efficient air handling and ventilation solutions geared to help your building breathe better and perform to its greatest potential.