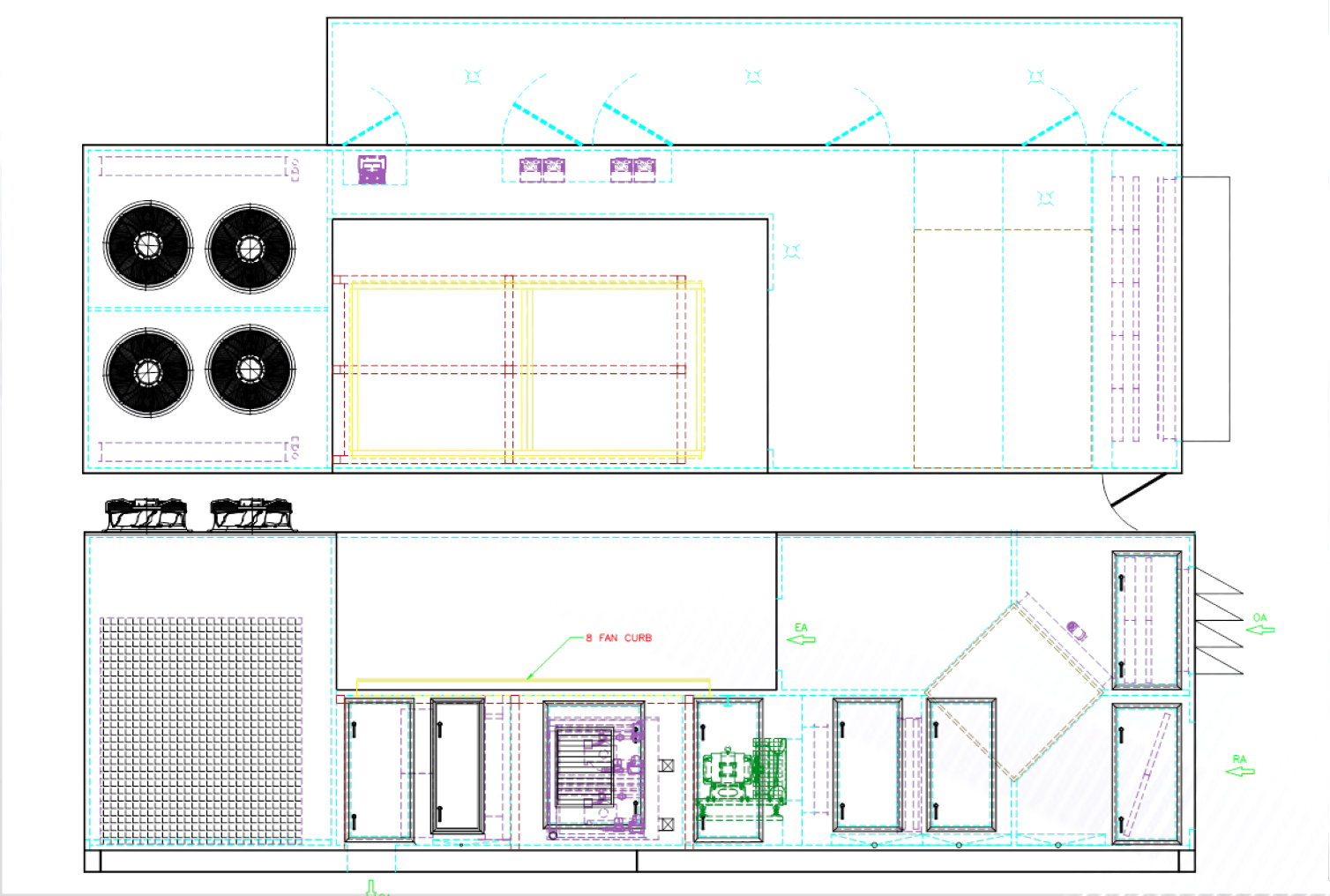

Custom ERV with High Plume Exhaust Fans

This XeteX project features a custom energy recovery ventilator with an aluminum flat plate heat exchanger for a pharmaceutical manufacturer.

Specifications

XHS-50-90-RT-BP-CD-HI-FF-AC

Height: 127”

Length: 322”

Width: 172”

Weight: 34,800 lbs

Supply CFM: 15,440

Exhaust CFM: 15,670

Energy Recovery: Aluminum flat plate heat exchanger

Cool Type: DX

Heat Type: IDF gas heater

Condenser: Air-cooled

This XeteX custom energy recovery ventilator services a lab space where precise control of the temperature and humidity are critical. Combining the high amount of outside air with the tight range of delivery conditions required, XeteX employed unique features into the design strategy to ensure reliable year-round desiccant dehumidification:

- Variable speed inverter tandem Scroll compressors

- Low ambient condenser kit

- 10:1 Indirect gas-fired heater

- Short absorption steam humidifier manifold

The high-plume lab exhaust fans are another noted unit feature. These specialized exhaust fans were provided by the rep and field installed on our pre-engineered mounting curbs with pre-wired electrical connections.

Unit Highlights

- Outdoor ERU with custom color exterior

- 2” injected foam panels

- Aluminum tread plate floor

- Epoxy-coated aluminum flat plate heat exchanger

- 80 tons air cooled condenser with low ambient kit

- Variable-speed tandem Scroll compressors

- Short absorption humidifier manifold with stainless steel liner

- Dual direct-drive supply fans

- Walk-in service vestibule

- Field-installed integral structural curb for lab exhaust fans

- Perforated liner in fan sections for quiet operation

- HEPA (99.97%) filtration