Custom Natatorium Dehumidification ERU for Healthcare

This featured XeteX project is a custom Natatorium Dehumidification Energy Recovery Unit for a healthcare application with split unit construction for transportation. Unit weight, unit dimension, duct locations and electrical load were critical in the design.

XeteX supplied multiple ERUs at a large Midwest aquatic facility. The main pool space is served by 144,000 CFM of air divided into three units operated in a master/slave configuration.

The dimensions of the larger units required that they be split into multiple sections for shipping. Instead of the typical “sliced bread” approach to unit splits, XeteX engineered a single split along the length of the unit. The main benefit of this custom feature was that all refrigeration circuits could remain intact during shipment and no field piping was required.

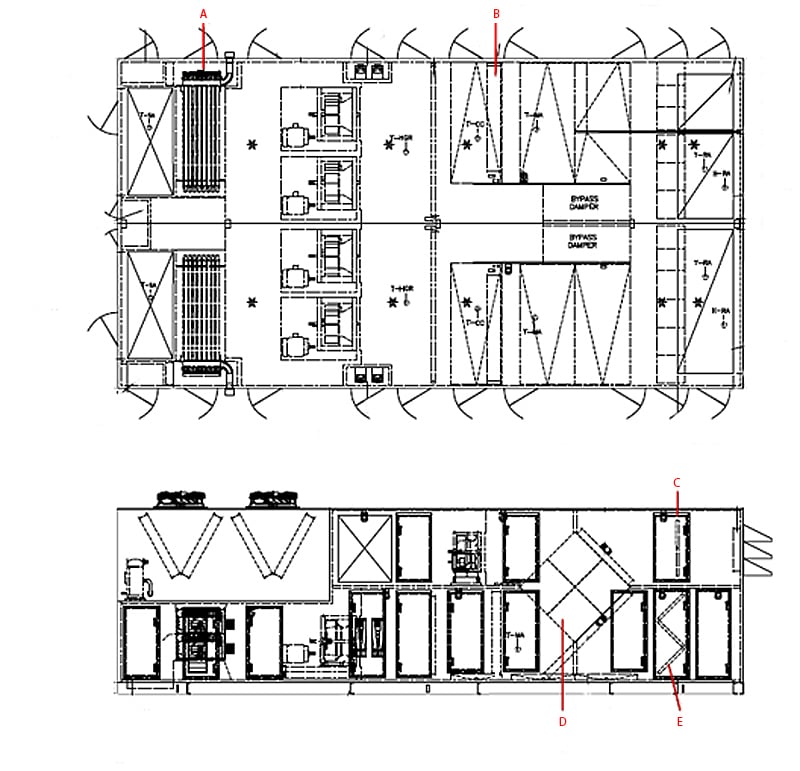

A look inside of this 60,000 CFM energy recovery pool dehumidification unit

Specifications

Height: 132”

Width: 234”

Length: 444”

Weight: 42,500 lbs

Supply CFM: 60,000

Exhaust CFM: 63,000

Energy Recovery: Flat Plate with Epoxy coating

Cool Type: Air Cooled 170 Tons

Summer Design (db/wb): OA= 88F/77F SA= 57F/56F

Heating Type: Indirect Gas 1600 MBH

Winter Design: OA= 0F SA= 95F

Unit highlights

- Outdoor unit with double wall thermal break construction with 2" mineral wool insulation

- 18ga painted acrylic exterior

- 16ga aluminum interior

- 4 circuits with tandem staged compressors

- 4 fan supply and exhaust array

- Factory supplied and programmed DDC controls

Components

A) 1600 MBH indirect fired gas heaters (10:1) w SS tubes

B) DX cooling coil with 316 stainless steel drain pan

C) 2” MERV 8 supply filter

D) Aluminum Flat Plate Heat Plate Exchanger with Epoxy coating

E) 2” Alum mesh return air filter